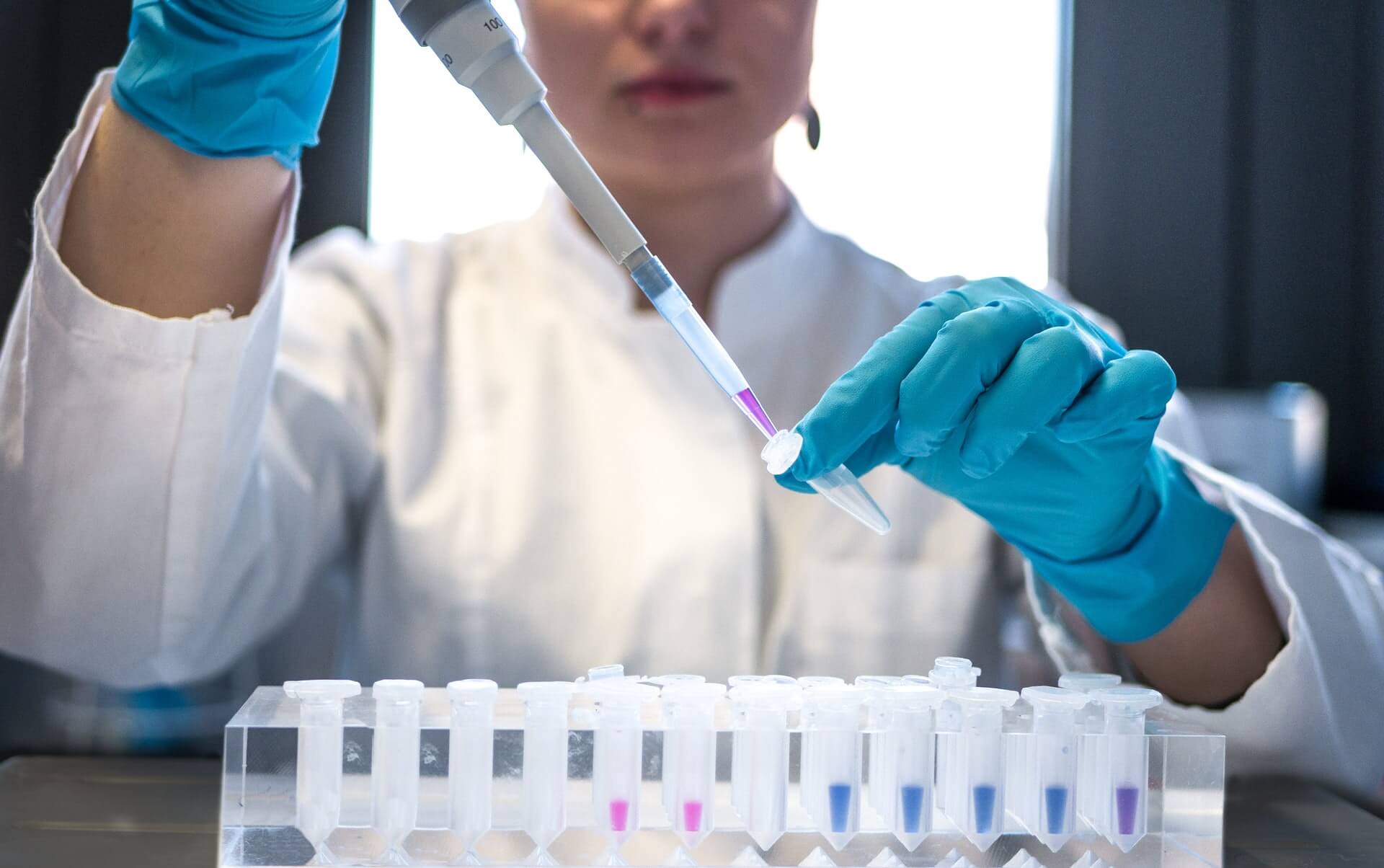

COD

Efficiencies

RO Reject Water Treated to Protect Bio Process

A biological treatment process can be the most cost effective way to treat high COD. But not if the water contains harmful chemicals which kill the essential treatment bacteria. This is where we come in.