Pharmaceuticals

Triton X-100

Removal of Triton X-100 from Pharmaceutical Wastewater

Removal of Triton X 100 from Pharmaceutical Wastewater is now required for companies which have authority to continue to use it following its ban by REACH in 2021.

Removal of Triton X 100 from Pharmaceutical Wastewater is now required for companies which have authority to continue to use it following its ban by REACH in 2021.

Those with the certificate need to entirely remove Triton X 100 from wastewater to comply. This regulatory amend has forced users of Triton X-100 to investigate options to fully remove it from wastewater to prevent its release into the sewer or aquatic environment.

This case study show how our Nyex Ellenox removes Triton X 100 from water to trace levels.

Triton X-100 (octylphenol ethoxylate or 4-tert-OPnEO) is a non-ionic surfactant with various uses in the pharmaceutical industry, including for cleaning and as an ingredient in some medicinal products.

A method currently adopted for the management of contaminated water is thermal oxidation. This process involves the water being collected and trucked off to a third-party specialist to be incinerated – a very expensive process with negative environmental implications.

This has led to pharmaceutical facilities looking for onsite wastewater treatment alternatives which are lower maintenance, as well as more cost-effective and sustainable.

Additional benefits for onsite treatment include complete traceability of hazardous waste for audit purposes and retaining complete control over compliance with upcoming legislation.

Jerome Budin

Wastewater consultant

Schedule a call with one of our wastewater treatment consultants at your convenience. Or you can send us an enquiry.

The aim of this project was to study the ability of the Nyex™-e system to destroy Triton X-100 from an aqueous solution to as low concentration as possible.

Oxidation experiments were conducted using a Nyex™-e to evaluate its effectiveness in destroying the Triton X-100.

HPLC and LCMS analysis was carried out on each sample to determine the concentrations of Triton X-100, starting from 16 mg/L. Experiments were conducted in a re-circulation mode and sampled from the container.

Pharmaceutical company, US

Arvia’s Nyex™-e system was deployed against this application. This process uses electrochemical oxidation in a single, scalable unit. A low electrical current is passed which fully mineralises the contaminants to H₂O, H₂ and CO₂.

Results are achieved without chemical dosing or the generation of sludge reducing costs in terms of labour, transport of chemicals and specialist waste disposal.

Tell us what organic compounds you need to remove from your water and our consultants will give their recommended approach which might involve:

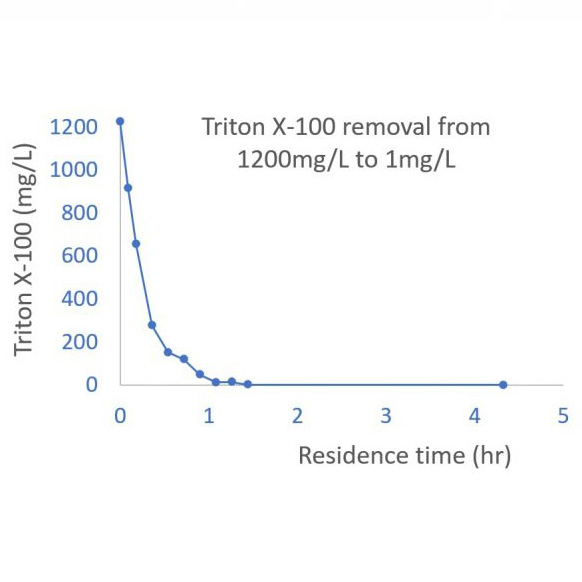

Two tests were done to show removal rates at low and high concentrations.

At a low inlet concentration of 16mg/L we reduced Triton X 100 to 0.01mg/L with only €0.70 per m³ in energy.

In addition, removal from a much higher concentration (1200 mg/L) was observed and a reduction to 1 mg/L was reached in about an hour and a half residence time with an energy consumption of 0.44 kWh.

This graph shows the treatment profile for the removal of the higher concentration of Triton X-100, still using a Nyex™-e system.

03.3.2023

"Arvia's technology is innovative and has been proven to solve our waste issue."

03.3.2023

Case study shows how our Nyex Ellenox system achieved over 99% removal rate of Triton X 100 (4-tert-OPnEO) from pharmaceutical wastewater.

05.9.2023

Case study shows how our Nyex Ellenox system achieved over 99% removal rate of 1,4-dioxane from industrial wastewater

We remove APIs and hard-to-treat micropollutants from wastewater for pharma, CDMOs, animal health, biotech and biopharma sectors.

We help specialty chemical companies clean their process water, removing active ingredients, biocides, recalcitrant COD and micropollutants.

Our industrial wastewater treatment process is very effective in removing organic chemicals such as pesticides, herbicides and insecticides.

We provide industrial wastewater treatment solutions removing biocides and other micropollutants in wash water and blowdown water.

Our aquaculture wastewater treatment removes pesticides used to treat sea lice, as well as medicines and off-flavours found in RAS facilities.